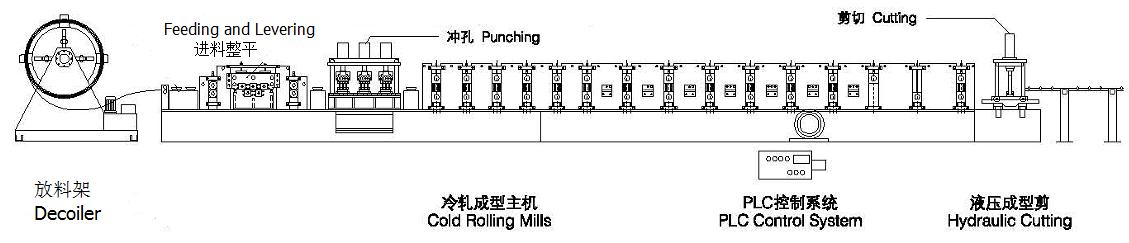

Rack Upright Roll Forming Machine

NO.1.Machine description

This machine takes galvanized steel or cold rolled steel as the raw materials,

through the a series steps to form it into a shelving profile with specific shape and size.

The forming steps devices include decoiler, Feeding and Leveling Device,

Hydraulic Punching device,main forming mill, hydraulic post-cutter.

The inverter controls the motor speed, the PLC system controls length and quantity automatically,

therefore, the machine achieves a continuous automatic production,

which is the ideal equipment for cold roll forming industry.

NO.2. Flow Chart

Decoiler →Feeing and Leveling Device→Hydrualic Punching device →Main forming machine

→ Hydraulic post-cutting→Exit rack.

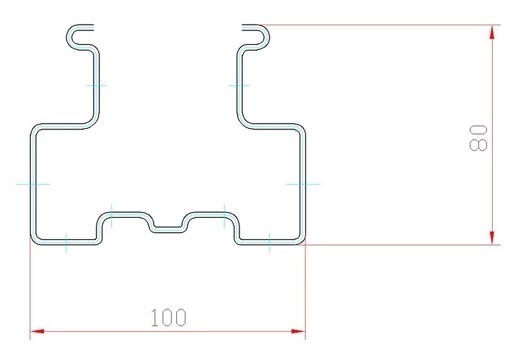

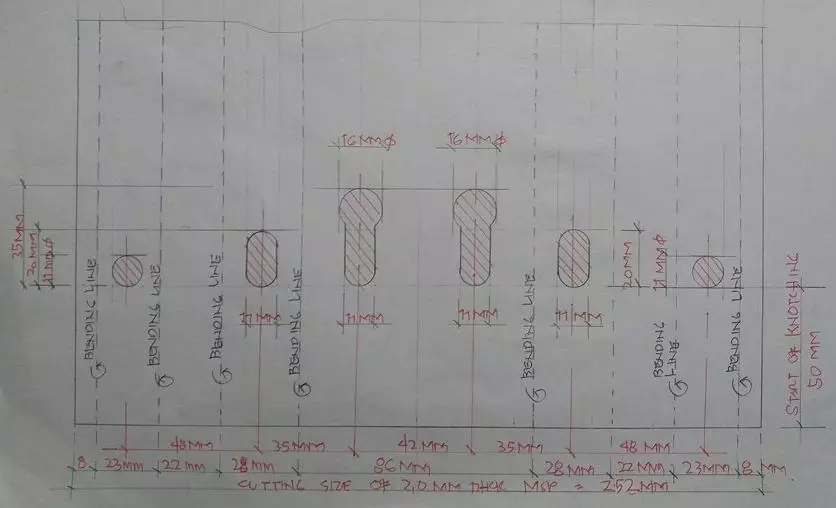

NO.3.Profile is as follow:

We could customize your specification.

Rack Upright Roll Forming Machine Technical Description of Different Parts:

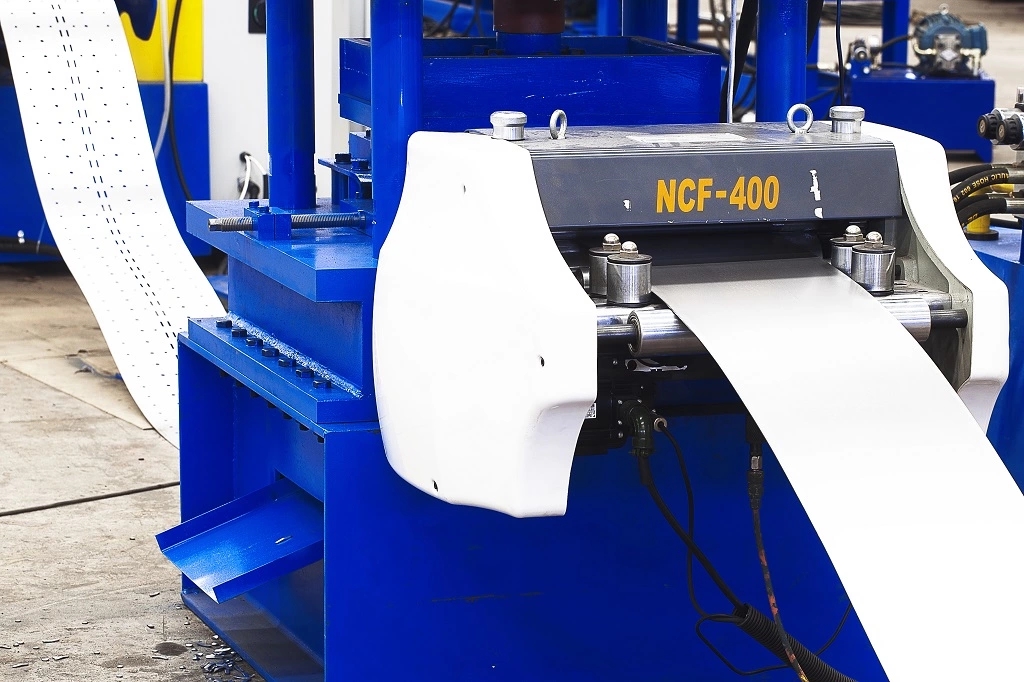

1) Rack upright roll forming machine Feeding and Leveling device

Brand: BMS Original: China

7rollers (up 3/down 4) ,for straightening the material.

Material of leveling roller: after quenched and chrome plated treatment the rigidity, its rigidity,

surface roughness and other mechanical properties have improved greatly. It consists of pinch rollerand leveling roller.

For pinch roller, it can adjust alone. For leveling roller, it adopts integral structure, setting two adjustable points

on its beginning and ending, and it can form a certain angle to improve its leveling quality.

At the beginning of the leveling, it has a pair of guide rollers, these rollers can adjust convenience.

--Servo Feeding

--Leveling Device

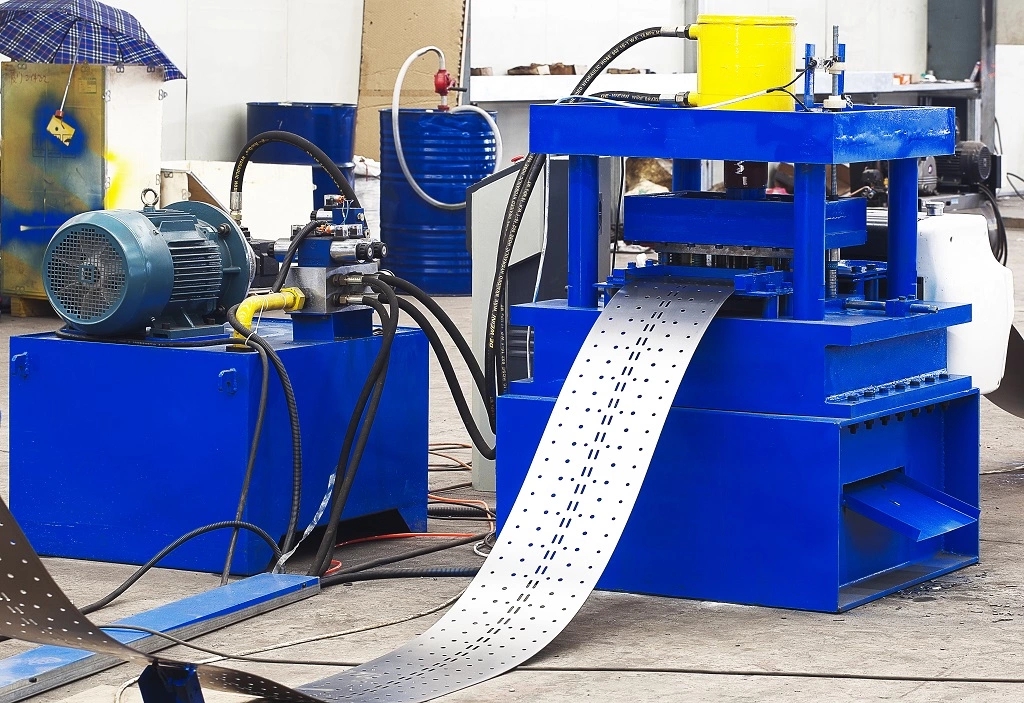

2) Rack upright roll forming machine Punching Device

Brand: BMS Original: China

3) Rack upright roll forming machineRoll forming system

Brand: BMS Original: China

Roll forming machine combined with body frame, transmission mechanism and forming rollers, etc.

a)The body frame is side wall type: main shaft diameter φ75mm,made from 45# steel, heat treatment. The lower shaft is main transmission by gear chain.

b)Transmission by motor driving, gear chain transmission.

c)Rollers manufactured from bearing steel GCr15,precision machined ,hard Chrome Coated,HRC50-60 with high durability

d) Body frame made from H450 type steel by welding with beautiful appearance, natural aging treatment and SR(stress relief) treatment.

e)The main machine forming step: about 18 steps to form, the side wall thickness: 18mm.

4) Rack upright roll forming machine Hydraulic Post-cutter

Brand: BMS Original: China

5) Rack upright roll forming machine PLC control system

Brand: BMS Original: China

Description: Computer control system, controlled by PLC.

The encoder control the width and height of the sheet automatically, and control the length positioning and cutting,

7inch touch screen operation, the precision is controlled within ±2.0mm

PLC: Delta brand (Taiwan)

Inverter: Delta brand (Taiwan)

7-inch Touch Screen: WEINVIEW brand (Taiwan)

Encoder: KOYO brand (Japan)

Switch bottom, Indicate light, Power supply, Intermediate relay, AC contactor,

Thermal relay: Schneider brand (German brand)

Air Switch: LG-LS(Korea brand)

6) Rack upright roll forming machineSample display

Brand: BMS Original: China

6) Rack upright roll forming machine exit rack

Brand: BMS Original: China

Un-powered,two units

After-sale service of rack upright roll forming machine

1. The warranty of rack upright roll forming machine

is two year after the client receives the machine.

Within the one year, we will courier the replacement parts to the client free of charge.

2. We offer technical support for the entire life of our machines.

3. We can send our technicians to install and train the workers in the clients' factories with extra cost.

Terms of trade

1. Minimum order quantity (MOQ): 1 piece

2. Delivery time: about 45 workdays

3. Port of loading: port of Xiamen

4. Type of payment: by T/T or by L/C

5. Export: Australia, UK, Ireland, Mexico, Brazil ,Israel ,Dubai, Russia ,India, Taiwan, Singapore,

Malaysia ,Thailand, Philippines, Myanmar ,Vietnam, South Africa, Mozambique,

Zambia, Zimbabwe, Nigeria, Egypt, Sudan, etc.

Certifications of BMS Roll Forming Machine

Gold supplier

Gold supplier

Facebook

Facebook  Twitter

Twitter  Linkedin

Linkedin  YouTube

YouTube  Blogger

Blogger  Instagram

Instagram