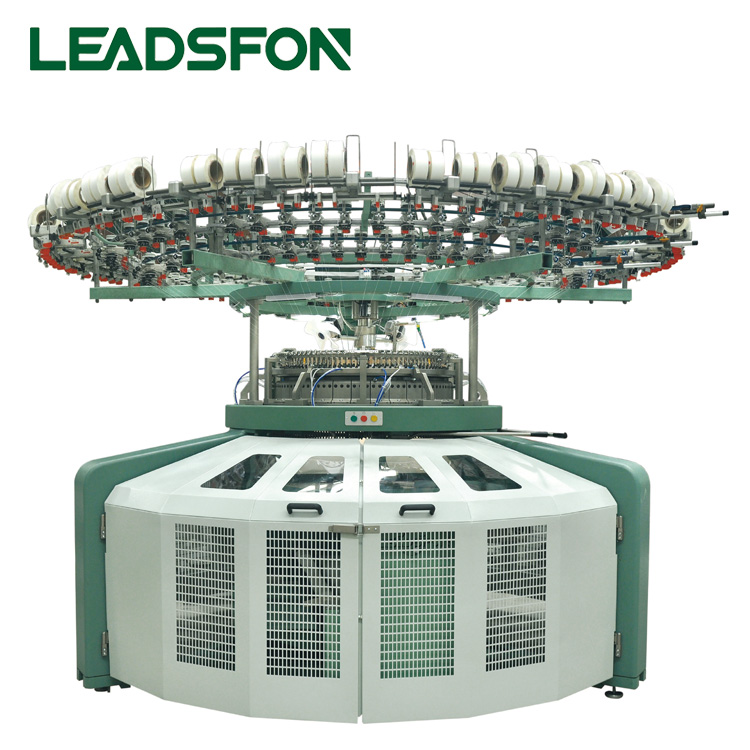

Professional Higher Speed Single Jersey Circular Knitting Machine

The range of this single jersey circular knitting machines covered here runs from simple mechanically controlled machines for plain fabrics through to sophisticated electronically controlled jacquard machines. Single jersey knitting machines come in a wide range of gauges and diameters for a wide range of applications.

Products Features

1. Select the original imported large plate gear and transmission system from Italy

2. Own patented screw lift adjustment system

3. Own patented double steel wire runway, reducing friction and running smoothly

4. Own patented take-down system, stable and efficient

5. The special angle steel frame makes the fuselage reach balance when running at high speed

6. Three sets of five-stage yarn feeding system

7. Four-track needle cylinder provides maximum flexibility and a variety of fabric options

8. A variety of fuselage to meet different production needs

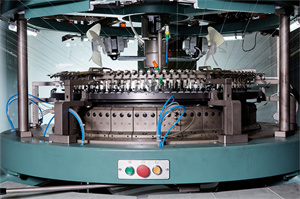

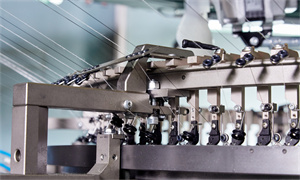

Products Photo

|

|

|

Applicable fabric

Our advantage

1. Single adjustment wheel debugging system for each channel;

2. DJR's unique design, the needle outlet point and yarn feeding angle are relatively fixed, and the needle pressing point can be adjusted independently, saving debugging work;

3. The overall adjustable yarn feeding ring is adopted, and the yarn feeding nozzle can be adjusted separately at the same time, which is easy to change the cloth type;

4.Unique big tripod structure, gears are absolutely meshed, making the equipment more stable and efficient;

5. The unique anti-skid setting of the yarn-feeding aluminum plate ensures the synchronization of the yarn-feeding wheels, eliminates the horizontal stripes on the cloth surface after the machine is stopped, and produces a smooth and high-quality cloth surface;

6.Unique high-speed take-down system, stable and efficient;

7. Four-track needle cylinder provides maximum flexibility and a variety of fabric options;

8. A variety of fuselage to meet different production needs.

Production example

DJR for 34inch, open width and 27rpm [unfinished,85%]

|

Structure |

Gauges (E) |

Yarn |

Weight (g/m2) |

Production kg/h |

|

RIB |

28 |

Cotton30/1 Ne |

125 |

24 |

Technical details

|

Type |

SJ3.0 |

|

Diameter [inch] |

26” - 42” |

|

No. Of feeders |

78F - 126F [3 feeds per inch ] (Example: 30” 90F) |

|

Speed factor [max] |

960 (Example : 32rpm at 30” ) |

|

Gauges [E] |

14GG-44GG |

Available frames

|

Tubular frame |

Open width frame |

||

|

Standard tubular frame |

Giant tubular frame |

Standard Open width frame |

Giant open width frame |

|

Frame for 550 mm Fabric rolls |

Frame for 680mm fabric rolls |

Frame for 330mm fabric rolls |

Frame for 680mm fabric rolls |

General supplier

General supplier

Facebook

Facebook  Twitter

Twitter  Linkedin

Linkedin  YouTube

YouTube  Blogger

Blogger  Instagram

Instagram