Industrial Magnetics Large Neodymium Magnets

| Place of Origin | Xiamen, China(Mainland) |

| Magnet Type | Sintered NeFeB / rare earth / Permanent |

| Composite | Neodymium-Iron-Boron |

| Grade | N35-N54( M, H, SH, UH, EH, AH series ) |

| Working Temperature | The Max. temp. is up to 80 / 100 /120 /150 / 230 celsius under different grade. |

| Tolerance | +/-0.03 to +/-0.15 |

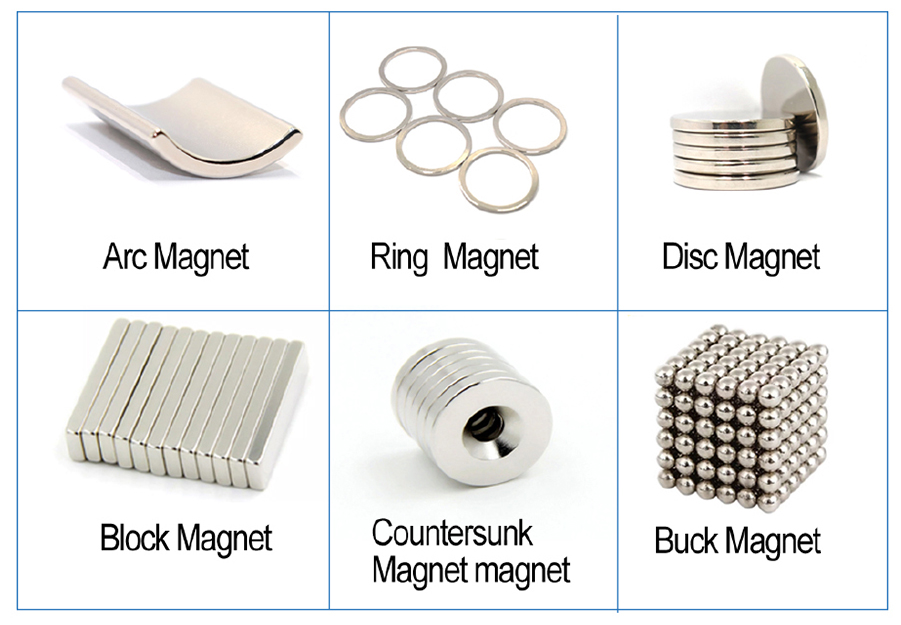

| Shape of Magnet | Disc, Cylinder, Block, Ring, Sphere(ball), Arc Segment(Tile) and more custom shapes |

| Size | various sizes custom-make welcome |

| Coating | Ni, Zn, NiCuNi, gold, silver, copper, epoxy, etc. |

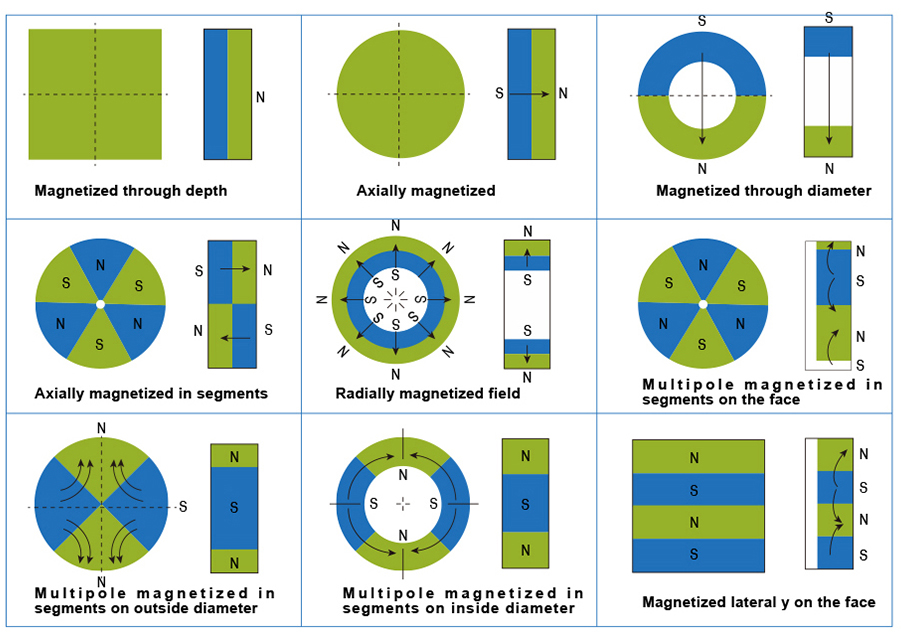

| Magnetization Direction | Axially Magnetized, Radially Magnetized(Diametrically), Multi-poles Magnetized or other customized |

| Certificate | ISO9001:2000,QS-9000:1998,SGS,RoHS,REACH |

| Application | Industrial Magnet, Toy Magnet, Health Magnet and more |

| Packaging | Antimagnetic Packaging / Neutral Packing / Custom-make welcome |

| Shipping Method | All shipping methods on offer.courier(TNT, DHL, FedEx, UPS), air or sea, with transit tracking regardless. |

| Lead Time | 10~25days |

Magnet Display

Neodymium-Iron-Boron (NdFeB) magnets are composed of neodymium, iron, boron, and a few transition metals. These kinds of permanent magnets are extremely strong and can be produced in different shapes and sizes (ie. arcs, blocks, discs, rings).

It has higher unit magnetic properties than other magnet and assures you of smaller size and lighter weight in designing devices.

Grade

cover N35-N52, N30M-N50M, N30H-N48H, N30SH-N45SH, N28UH-N40UH, N28EH-N38EH.

Size and Shape

D3--D280mm(round)Cylindrical,

Ring, Square, Holed Square, Watt, Arch, or Customized.

Coating

Nickel, Nickel copper-nickel, Zinc, Golden, Black epoxy, Grey epoxy, Phosphating, and so on.

n40 neodymium magnets

Direction of magnetization

Through the thickness or through the diameter.

A. Magnetization thickness

B. Axial magnetization

C. Symmetric magnetization

D. Multipole magnetization

E. Radial magnetization. Special requirements for custom magnetization

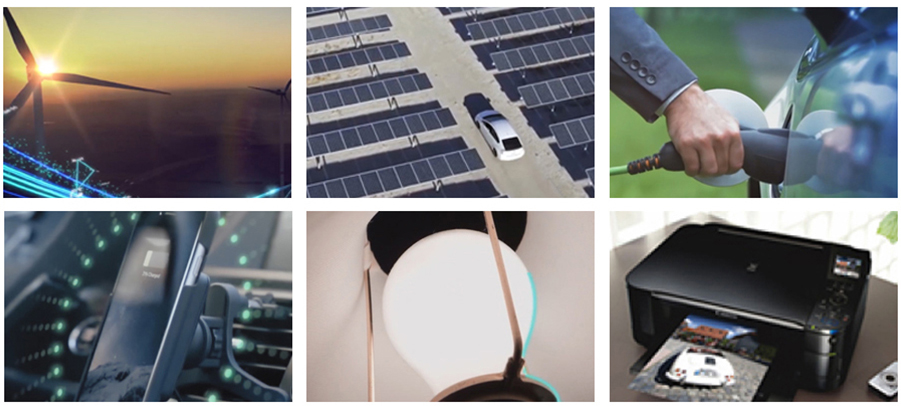

Application of NdFeB magnet

Toys, Package, Printer, Switchboard, Phone, Vcoil motors (VCM's) in hard disk drives, High performance(maglev, linear and rotary) motors, Bearings, Eddy-current brakes, Brushless DC motors, Magnetic separation, Magnetic resonance imaging, Sensors, Loudspeakers, Jewelry industry and etc.

Advantage

1) Excellent temperature stability

2)Small size and lightweight

3)Strong magnetism

4)Relatively high energies characterize

5) High performance-to-price ratio, widely used

Our Equipment

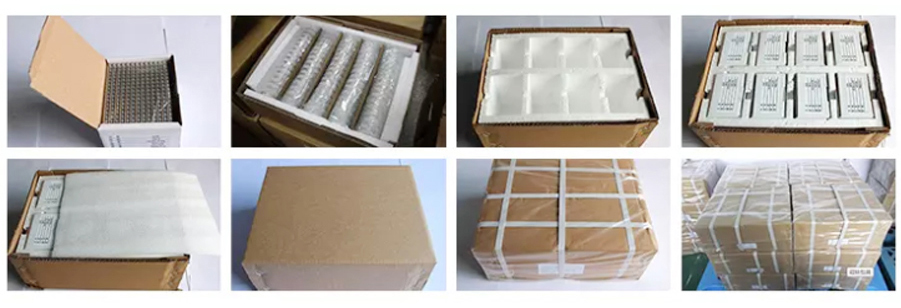

Packing of Neodymium Magnet

Magnet Export standard foam-filled cartons supplied standard.

Tailored packaging offered per customer request.

Packages appropriate to both air and sea shipment available.

Shipping Methods

All shipping methods on offer. courier(TNT, DHL, FedEx, UPS), air or sea, with transit tracking regardless.

Shipper or freight forwarder may be appointed by either purchaser.

Certificates

Exhibition

FAQ

Q: How long is your lead time?

A: Generally it is 5-10 days if the goods or materials are in stock. or it is 20-25days for new production, it is according to the order quantity.

Q: What is your MOQ?

A: We have no strict MOQ, if we can do, we will try our best to cooperate; if any questions as small quantity, we will be open to communicate with our customers for a better solution.

Q: What are your terms of payment?

A: Payment<=10,000/sd,100% in advance, paymcnt>=10,000usd,30%t/t in advance, balance before shipment.

Q: Will magnets lose their power over time?

A: Modern magnet materials do lose a very small fraction of their magnetism over time. for samarium cobalt materials, for example, this has been shown to be less than 1% over a period of ten years.

Q: What might affect the strength of a magnet?

A: The factors can affect a magnet's strength: heat radiation strong electrical currents in close proximity to the magnets other magnets in close proximity to the magnet(Neodymium magnets will corrode in high humidity environments unless they have a protective coat-ing-) shock and vibration do not affect modern magnet materials unless sufficient to physically damage the material.

Q: Can a magnet that has lost its magnetism be re-magnetized

A: Provided that the material has not been damaged by extreme heat. the magnet can be re-magnetized back to its original strength.

Q: Can I make a magnet that I already have any stronger?

A: Once a magnet is fully magnetized, it cannot be made any stronger-it is"saturated." in that sense, magnets are like buckets of water; once they are full. they can't get any "fuller."

Q: Can you supply magnets with one pole on the outside and one on the inside?

A: Ring magnets can be magnetized this way and they are referred to as radially magnetized.

General supplier

General supplier

Facebook

Facebook  Twitter

Twitter  Linkedin

Linkedin  YouTube

YouTube  Blogger

Blogger  Instagram

Instagram