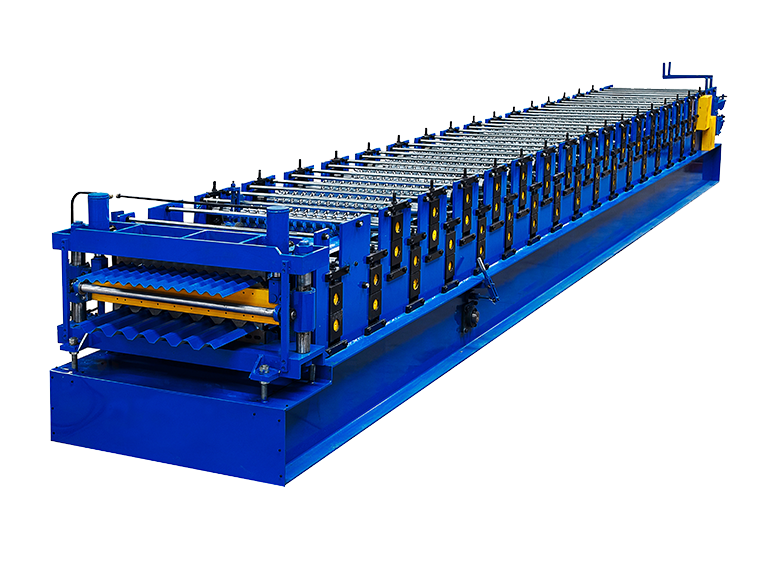

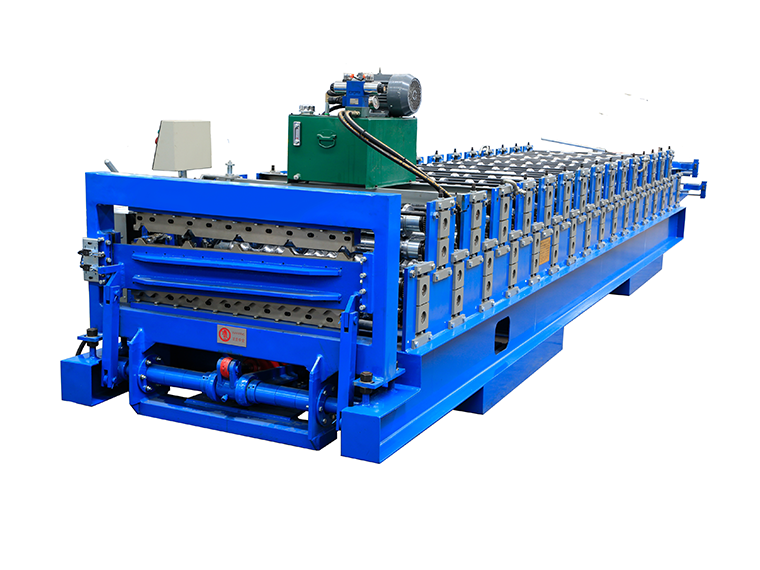

Details of Double Layer Roof Panel Machine

Material Thickness(&):0.3-0.8mm

Applicable material:Applicable material:Painting Steel,

Galvanized Steel,Tension Grade: 245Mpa or 550Mpa,

Machine Components

Max. feeding width: 500mm, coil ID range 470mm±30mm

Capacity: Max. 3Ton

2) Cold Rolling Mills:

With feeding material guide, body frame made from 350# H type steel by welding

Rollers

manufactured from bearing steel GCr15,precision machined,hard Chrome

Coated with thickness 0.04mm(for longer life and anti-rust);Shafts manufactured from 45#,Main shaft Diameter=φ85mm,precision machined

Motor Driving,Gear chain transmission, 18/18 forming stations and 7 rollers(3 upper rollers and 4down rollers)for straightening and levelling)

Forming speed approx.12-18m/min

3)Hydraulic Cutting device

Cutting tool material: Cr12Mov, Heat treatment

4)PLC Control System

(Touch screen brand:Taiwan WEINVIEW,Inverter brand:Finland VOCAN/Denmark Danfoss

,Encoder brand: Japan Koyo)

Control the quantity and cutting length automaticallyCombined with: PLC, Inverter, Touch Screen, Encoder, etc

Cut-to-length tolerance≤±1mm

Control Voltage 24V

5) Exit Rack

Un-powered, two units

Terms of trade

1. Minimum order quantity (MOQ): 1 piece2. Delivery time: about 30 workdays

3. Port of loading: port of Xiamen

4. Type of payment: by T/T or by L/C

5. Export: Australia, UK, Ireland, Mexico, Brazil ,Israel ,Dubai, Russia ,India, Taiwan, Singapore, Malaysia ,Thailand, Philippines, Myanmar ,Vietnam, South Africa, Mozambique, Zambia, Zimbabwe, Nigeria, Egypt, Sudan, etc.

Gold supplier

Gold supplier

Facebook

Facebook  Twitter

Twitter  Linkedin

Linkedin  YouTube

YouTube  Blogger

Blogger  Instagram

Instagram