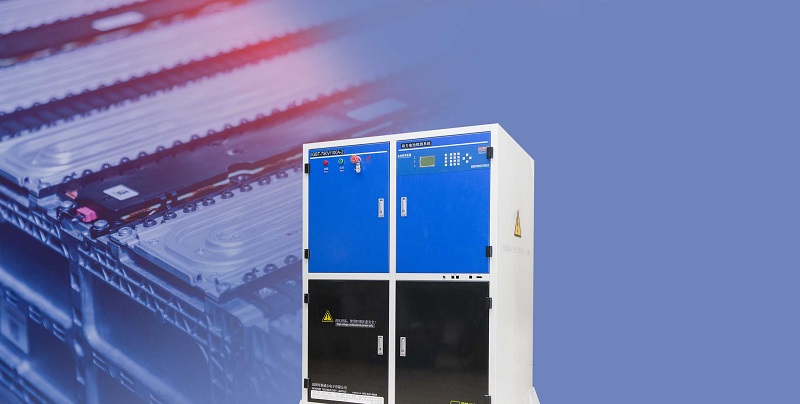

Battery Pack Regenerative Charge and Discharge Testing System

ACEY-CE-7000-R2 Charge and Discharge Module & PACK Testing (Energy-Feedback)

For EV&PACK, high voltage and high current power battery testing system

Specially for Battery pack testing. As high power battery testing system, IGBT7000 adopt IGBT( Insulated Gate Bipolar Transistor ) technology which is much different from traditional power devices and control methods. Much stable and reliable testing control performance decide the best testing solution for power battery and energy storage battery.

Using digital signal processor(DSP) as key digital circuit

The key control circuit of IGBT system use digital signal processor(DSP) as key digital circuit. Based on TI's C2000 platform,its abundant peripheral resources and high-speed digital computing capabilities enable it to meet the needs of data processing and system control. Send simulation to be tested and digital signals to DSP, others task could be carried out by client software.

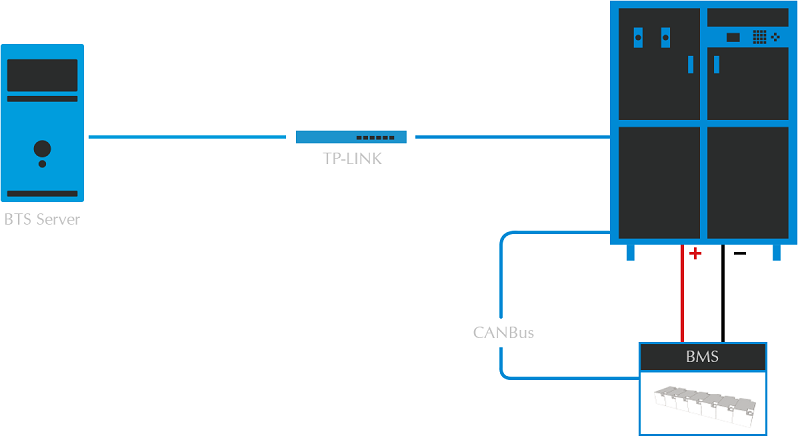

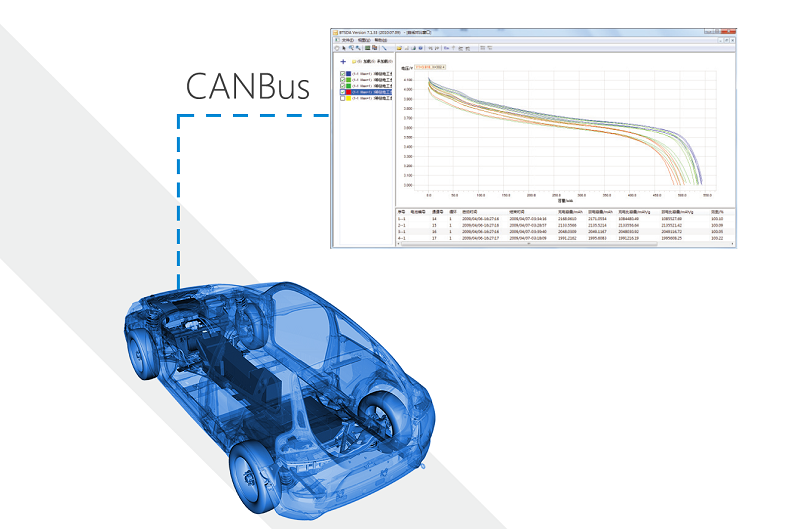

Via CANBus communication, real-time monitoring of battery performance has come true.

For some battery packs without BMS, our auxiliary voltage and temperature sensors will help you to detect the voltage and temperature of every single cell

CANBus is a communication mode which is widely used in automotive electronics. Through the CANbus interface, the middle machine obtains the real-time voltage and temperature of the battery from the BMS (battery management system), so as to carry out real-time monitoring and achieve the purpose of protecting and testing batteries.

CANBus is mainly used to test PACK battery with BMS, such as EV&Pack battery testing.

Product Display

Bronze supplier

Bronze supplier

Facebook

Facebook  Twitter

Twitter  Linkedin

Linkedin  YouTube

YouTube  Blogger

Blogger  Instagram

Instagram