Magnetic Grill, Magnetic Grate, Grate Magnets, Hopper Magnet description:

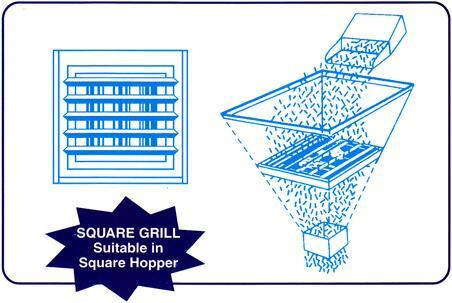

The hopper magnet is mainly used to remove iron impurities in hoppers, feeding troughs, and floor spaces, and can effectively remove free-flowing powders and iron impurities in small particles. The grate magnet is equipped with a beautiful appearance and reasonable distribution of magnetic bars, which can provide a high-strength magnetic field to attract the iron powder, iron filings, and other small pieces of magnetic metal in the flowing material.

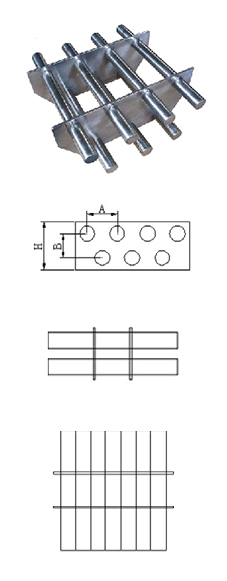

The stainless steel seamless pipe and the outer frame are welded by skilled workers to form a strong whole. It can be installed on the production line, or simply placed in the hopper or material box, and can be easily taken out and cleaned. The grate magnet is made of materials, and the surface is corrosion-resistant, which can reach the cleanliness level of food and even medicine. GME’s hopper magnet usually uses 25mm diameter magnetic rods, arranged in parallel at a center spacing of 40mm.

Magnetic Grill, Magnetic Grate, Grate Magnets, Hopper Magnet style:

In practical applications, the commonly used magnetic grid forms are:

1. Drawer-type grille iron remover, the magnetic grille is fixed in the stainless steel frame to achieve the purpose of a convenient connection with the production pipeline and convenient cleaning and operation.

2. Fluid pipeline type iron separator, the magnetic grid is placed in a three-way stainless steel barrel container, and it is convenient to transport liquid or powder to the pipeline through the flange, quick connection, or pipe thread of the stainless steel barrel container. The connection is not only easy to clean and operate, but also does not affect the flow and flow rate of the pipeline.

3. Rotary grille iron remover, through the decelerating motor, to drive the magnetic grille to rotate, thus effectively avoiding the bridging and blockage of some powder materials with poor fluidity when they flow through the ordinary magnetic grille or drawer type grille separator In the case of the pipeline, the speed can be customized according to the actual operating conditions, but the speed is not too fast.

4. The easy-to-clean magnetic grid is generally used for square magnetic grids. A stainless steel sleeve is added to the surface of the round magnetic rod. When cleaning, the magnetic rod of the magnetic grid is pulled out of the stainless steel sleeve. , The magnetic impurities adsorbed on the surface of the magnetic grid will easily leave the surface of the magnetic rod.

Magnetic Grill, Magnetic Grate, Grate Magnets, Hopper Magnet product features:

1. The material of the rack and pipe is 304 or 316L stainless steel, corrosion-resistant, and pollution-free.

2. Finest of Magnetic Materials used meeting IMA/MMPA

3. The standard hopper magnet is composed of a metal frame and a 25mm diameter magnetic rod arranged at a distance of 50mm from the center, then screwed and assembled or welded, can be designed with baffle or guide rod magnetic frame.

4. The internal use of strongly magnetic materials, the surface magnetism is up to 12000GS, the standard size of the magnetic rod is Φ 25 mm; the external stainless steel surface has no internal leakage and tracheotomy, and it is polished and bright.

5. The surface of the hopper magnet can be polished to meet the requirements of food or medicine use level.

6. The maximum working temperature of the product is ≦80℃. If necessary, it can also meet the special needs of customers. The maximum working temperature can reach 80℃-350℃.

7. Ordinary type, easy-to-clean type, guide rod or guide plate type, square type, round shape, and other special specifications required by customers can be provided.

8. No energy consumption, no pollution, can be installed at any position on the production line that can be in contact with materials, saving space and convenient installation, mainly using rare earth alloy neodymium iron boron as the magnetic source, strong magnetic force, simple structure, and long service life.

Working principle of Magnetic Grill, Magnetic Grate, Grate Magnets, Hopper Magnet:

The magnetic filter hopper magnet is made of high-quality stainless steel tubes and high-B rare earth alloy neodymium iron boron and is made by a special manufacturing method.

And the combination is fixed on the fixed frame to form a hopper magnet. When the iron-containing material passes, it is attracted by the magnetic rod, and the iron-containing material is firmly adsorbed on the tube wall to ensure the integrity of the equipment and the safety of the product.

Round Grate Magnet specification for standard plastic material hopper:

Square Magnetic Grate

| Magnetic grate size | Number of layers | Magnetic grate height H | Magnetic rod center distance A | Magnetic rod center distance B | Number of magnets |  |

| 100*100 | 1 | 40 | 50mm | 40mm | 2 | |

| 2 | 80 | 3 | ||||

| 150*150 | 1 | 40 | 3 | |||

| 2 | 80 | 5 | ||||

| 200*200 | 1 | 40 | 4 | |||

| 2 | 80 | 7 | ||||

| 250*250 | 1 | 40 | 5 | |||

| 2 | 80 | 9 | ||||

| 300*300 | 1 | 40 | 6 | |||

| 2 | 80 | 11 | ||||

| 350*350 | 1 | 40 | 7 | |||

| 2 | 80 | 13 | ||||

| 400*400 | 1 | 40 | 8 | |||

| 2 | 80 | 15 | ||||

| 450*450 | 1 | 40 | 9 | |||

| 2 | 80 | 17 | ||||

| 500*500 | 1 | 40 | 10 | |||

| 2 | 80 | 19 |

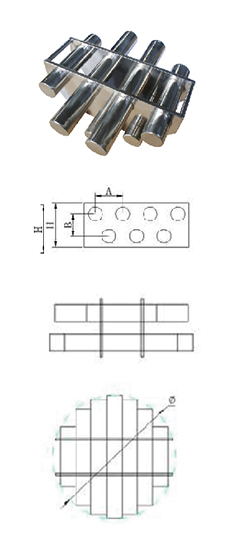

Round Magnetic Grate

| Magnetic frame diameter Ф | Number of layers | Magnetic frame height H | Magnetic rod center distance A | Magnetic rod center distance B | Number of magnets |  |

| Ф100 | 1 | 40 | 50mm | 40mm | 2 | |

| 2 | 80 | 3 | ||||

| Ф150 | 1 | 40 | 3 | |||

| 2 | 80 | 5 | ||||

| Ф200 | 1 | 40 | 4 | |||

| 2 | 80 | 7 | ||||

| Ф250 | 1 | 40 | 5 | |||

| 2 | 80 | 9 | ||||

| Ф300 | 1 | 40 | 6 | |||

| 2 | 80 | 11 | ||||

| Ф350 | 1 | 40 | 7 | |||

| 2 | 80 | 13 | ||||

| Ф400 | 1 | 40 | 8 | |||

| 2 | 80 | 15 | ||||

| Ф450 | 1 | 40 | 9 | |||

| 2 | 80 | 17 | ||||

| Ф500 | 1 | 40 | 10 | |||

| 2 | 80 | 19 |

Magnetic Grill, Magnetic Grate, Grate Magnets, Hopper Magnet Easy Clean:

The hopper magnet is made of multiple magnetic rods fixed by steel plates. Many customers feedbacks that the conventional strong hopper magnet is not convenient to clean, for this we introduced the easy-removable hopper magnet. It greatly reduces the cleaning time of the magnetic material on the rods and can improve the efficiency of the work well.

The easy to clean magnetic grate is a combination of stainless steel empty frame + a complete unconventional magnetic shelf. GME’s magnetic grates are cut out by laser cutting technology and shaped by manual skilled welding, with small dimensional tolerance and high quality.

How to choose surface Gauss:

If the metal you want to attract is Screw, thread, or nut, 2500-2800GS.

If the metal is an iron powder, 10,000GS

For 2500-2800GS, it is often by not welding type as below:

For 10,000GS, it is often by welding type as below:

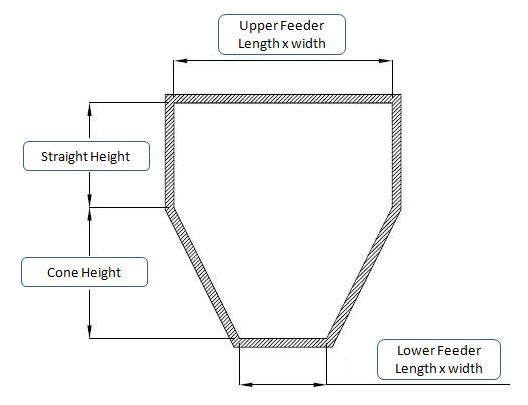

There is no standard size for rectangle hopper Magnet, please confirm the size of the hopper:

Rectangle Hopper Magnet Demonstration:

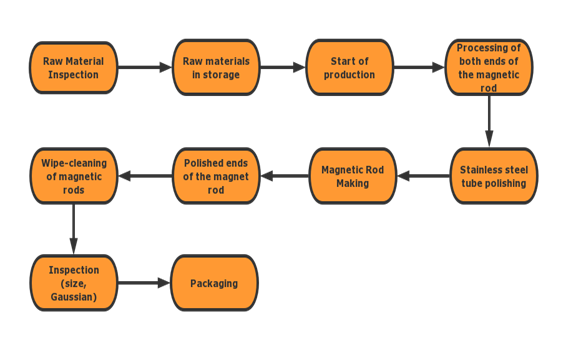

Production process of Magnetic Grill, Magnetic Grate, Grate Magnets, Hopper Magnet:

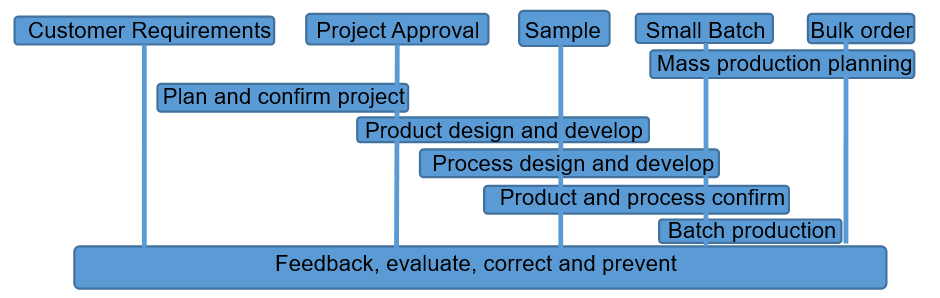

Internal Management System-Form an APQP:

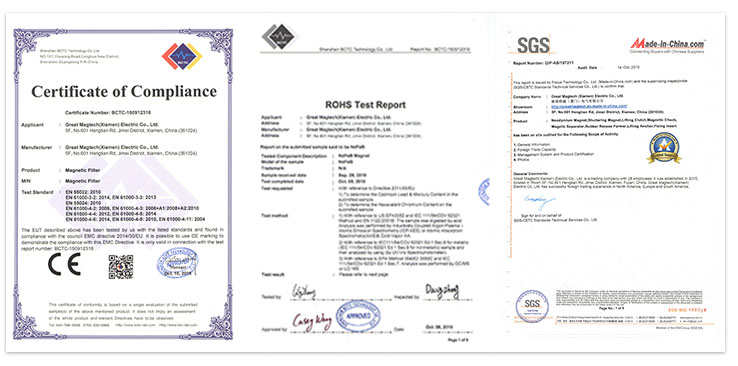

Quality Management System

We always believe that a small magnet can make a big difference, so we conduct every production process carefully. That’s our eternal pursuit and promise to our clients. In May 2014, Our factory has passed Quality Management System TS16949 and in October, our factory passed ISO14001, ISO9001 and GB/28001.

Our factory performs the process management based on the customer orientation emphasizing the process control, quality cost management, and waste reduction. We also use the Advantaged Product Quality Planning(APQP), Potential Failure Mode and Effects Analysis (FMEA), Statistical Process Control(SPC) Production Part Approval Process(PPAP), Measurement System Analysis(MSA) Error Proofing method to prevent the defects from occurring.

The surface cleanliness reaches Ra0.6=600 mesh. It is suitable for medicine and food. The surface treatment has 4 processes:

1. Coarse grinding

2. Fine grinding

3. Coarse polishing

4. Fine polishing.

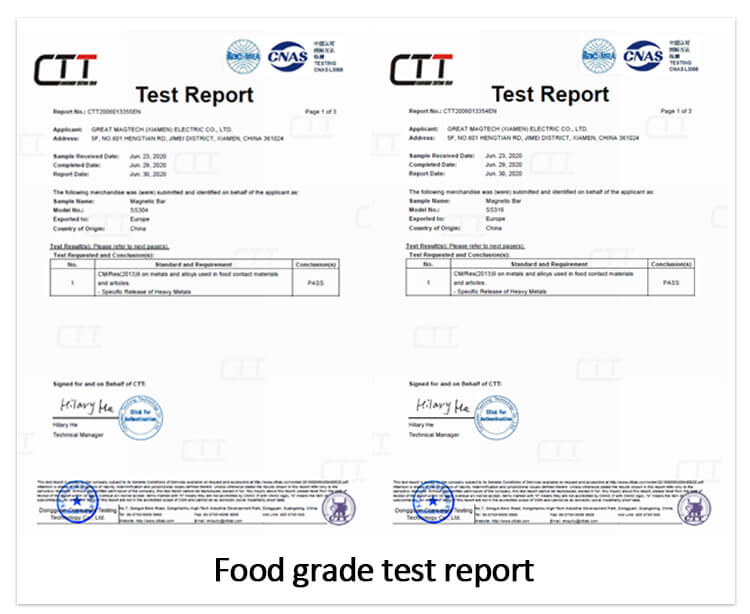

Food Contact Stainless Steel Tubes

Different from the magnetic bar on the market, the stainless steel used in our products is food-grade stainless steel, which means more environmental protection and durability. It can be used in direct contact with food and is harmless, and the quality has been certified.

Past Project

1. 5R Management Material Procurement System.

2. Our purchasing manager has more than 7-year purchasing experience and rich in experience in quality control and the advantages of different factories and different products, and different quality levels.

3. According to your actual need, GME would select our most suitable factory for you. Providing professional technical support is one of our values.

How to choose a Magnetic Grill, Magnetic Grate, Grate Magnets, Hopper Magnet:

Hopper Magnets are made up of a combination of multiple magnetic rods, so the main thing to judge a Grate Magnet is the quality of the rods. Of course, in addition to the magnetic rods, it is also necessary to look at the combination of the magnetic holder sequence design.

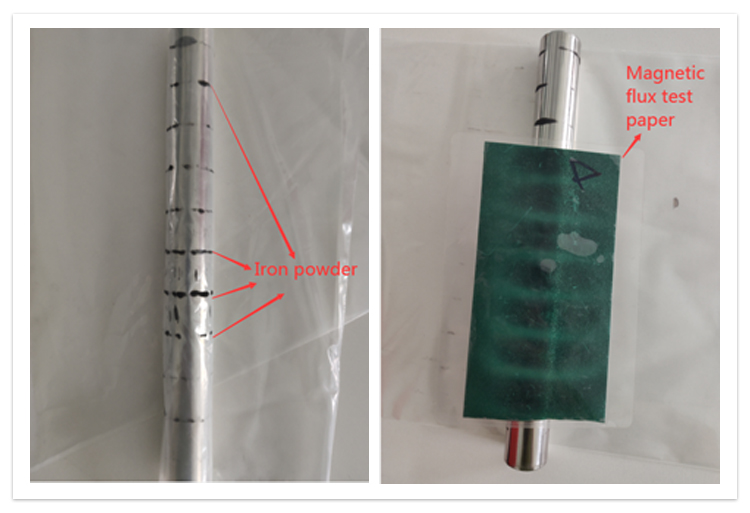

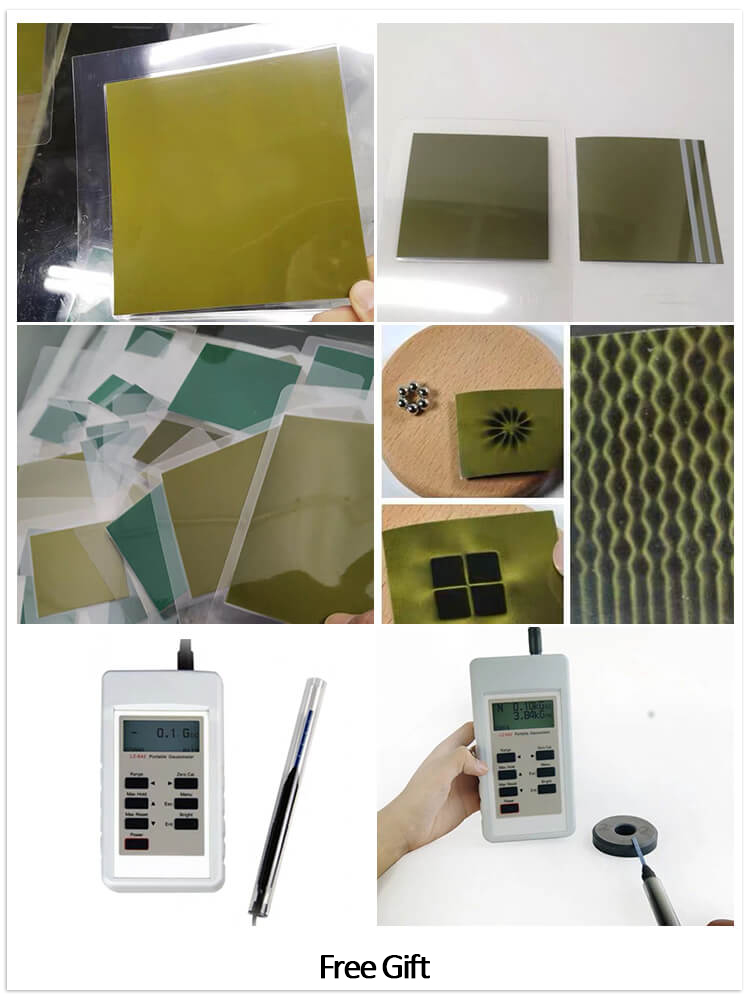

The magnetic rods are made of strong magnets and magnetic guide plates arranged in a prescribed order, but because the rods are sealed, it is impossible to disassemble them to see the inside condition. So how do we determine if the magnet and magnetic guide of this rod is evenly ordered and if the magnetic induction line is even? At this time, we can look at the magnetic lines, you can sprinkle a little iron powder, the distribution of iron powder is the distribution of magnetic induction lines, so as to judge whether the order of the magnets and iron sheet of this magnetic rod is reasonable.

In addition to the magnetic induction wire, we also need to see if the exterior of the magnet is smooth and free of burrs, sealed in place. The magnet material inside should not be exposed on the outside to avoid direct contact with the material, which may pollute the material and the environment.

In order to have a good experience when you buy a Grate Magnet, please tell us your usage situation, because the application environment, the design of the magnetic rack, and the magnetic bar have different requirements.

For delivery

Our warehouse has a large amount of conventional raw materials and stainless steel pipes. We can directly produce hopper magnet according to your needs without repurchasing raw materials.

The delivery time of conventional products is usually 5-7 days. We can provide you with multiple modes of transportation such as air, sea, and express or land.

Package of Magnetic Grill, Magnetic Grate, Grate Magnets, Hopper Magnet:

We will choose different packing methods according to the different shipping methods to ensure that the products will not be damaged during shipping. So far, our customers have 0 complaints about the packaging of our products.

1. By express or air:

Bubble bag-foam board-iron sheet insulation--double corrugated box

2. By sea:

Wood Carton

Pallet:

After-sales Service:

1. Our response will be always available within 12 hours.

2. Products and packing pictures before shipment.

3. Offer Invoice, packing list, and documents timely.

4. Shipping notice and goods arrival notice at timely.

5. Magnet application suggestion and tips.

After-Sales Service-Complaint System:

1. Call the client within 12 hours.

2. Communicate with the client to know what problem happens,

quantity, and in which order or batch?

3. Ask clients to take detailed pictures.

4. Internal checking and figure out why the problem happened.

5. Offer a suitable and satisfying solution, replenishment, or refund.

6. Apology and avoid problems in future orders.

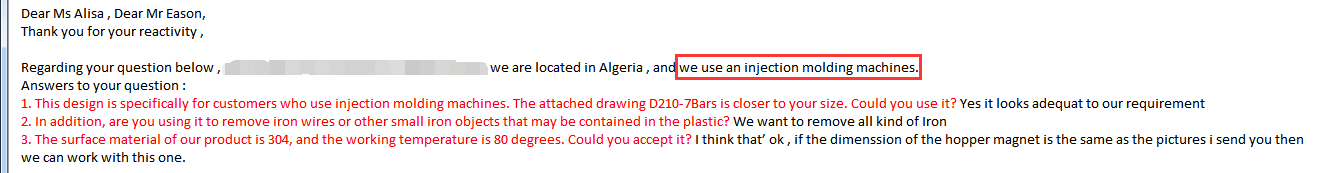

Cooperative customer case:

(Customers used in coffee production)

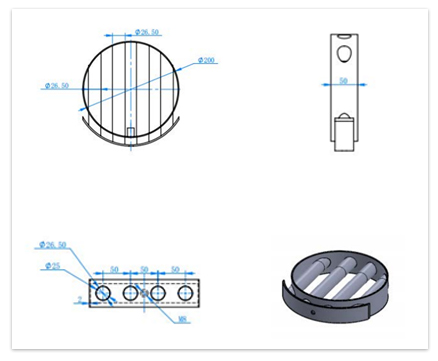

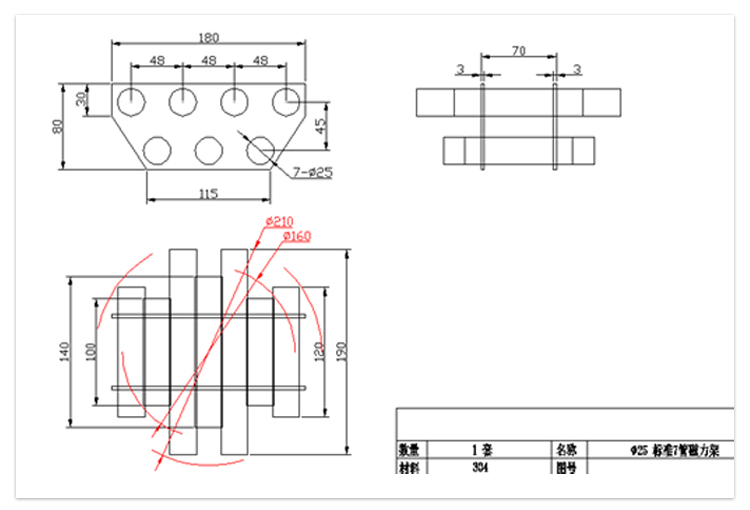

We can design solutions for customers according to their needs and provide drawings for customers to confirm.

The design drawings we provide to customers

3. Customers used in injection molding machines.

For dealer customers:

We offer a free Gauss meter and magnetic pole piece to customers who work with us for an annual turnover of $50,000.

How to select and identify 304 and 316 stainless steel

1. Whether it contains MO: Stainless steel screw 316 contains more MO than 304, and its corrosion resistance and acid and alkali resistance are better than 304;

2. Nickel content is different: ≥10%: 316 material, between 8% and 10% is 304 stainless steel;

3. The energized potion identification experiment: based on chemical analysis, with the aid of batteries to make the material surface oxidation reaction, through the appropriate control technology to make the measured elements and reagents to generate colored chromium compounds. (Which N8 test 304 stainless steel, energized point solution after the potion becomes red, the material reaches 304, the potion becomes yellow or colorless, the material does not reach 304; M2 test 316 stainless steel energized point solution after the potion becomes red, the potion becomes black or red disappears instantly, the material does not reach 316).

304 and 316 have different performance

304 stainless steel can resist sulfuric acid, phosphoric acid, formic acid, urea, and other corrosion, suitable for general water, control gas, wine, milk, CIP cleaning fluid, and other corrosive small or non-contact materials.

316L stainless steel in 304 based on the addition of molybdenum, can significantly improve its resistance to inter-granular corrosion, oxide stress corrosion and reduce the welding of hot cracking tendency, it also has good resistance to chloride corrosion. Commonly used in pure water, distilled water, pharmaceuticals, sauce, vinegar, and other high health requirements, the media corrosion performance of the occasion.

Different ways of using stainless steel 304 and stainless steel 316

304 is mainly used in indoor and general outdoor environments, while 316 is used in the marine, chemical, food, and medical industries.

FAQ

1. Why can't the Gauss reach on some hopper magnets?

You can sprinkle some iron powder on the hopper magnet to make it easier to measure the Gaussian value

2. Why is there a slight bump on the magnetic rod surface?

The magnetic rod has a Gaussian value of 12,000 GS or more, and its internal magnet has a strong magnetic field, so it requires a larger sized magnetic sheet to make it, which causes a slight unevenness in the surface of the rod, but does not affect its use.

General supplier

General supplier

Facebook

Facebook  Twitter

Twitter  Linkedin

Linkedin  YouTube

YouTube  Blogger

Blogger  Instagram

Instagram