Please Click Here to View the Video

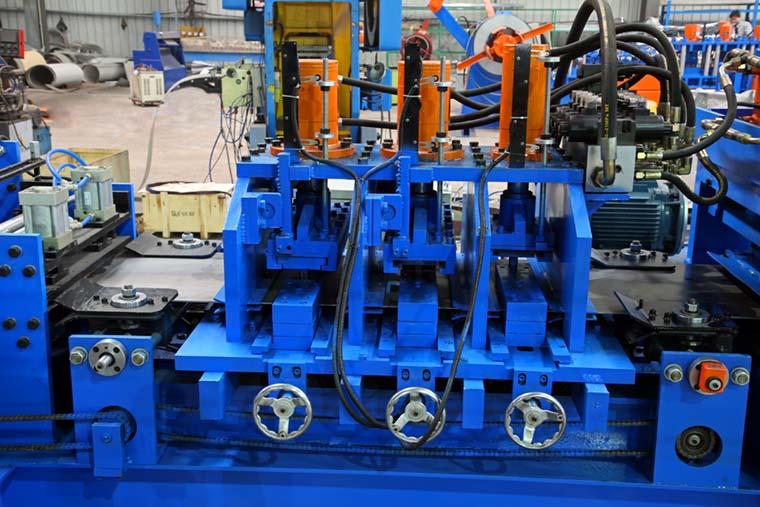

5mm Thickness Automatic C Purlin Roll Forming Machine

1. Advantages of C Purlin Machine

1) Produce purlins of different sizes without changing the rollers or pads.

2) Different sizes will not change

3)Simple operation and low maintenance cost

4)Unlimited size (any size within the machine range), simple size

5)Hand-punch holes at any position on the board side and flange side

2. Machine Components

Machinery order

1) Straightening with servo control roller feeder

Brand: BMS Original: China

7 straightening rollers (upper 3 and lower 4)

11KW servo motor (China famous brand Huichuan) feeding,

Remarks: electric adjustment and positioning, no need to connect to PLC

And power feed (gas source provided by contribution)

2) Three-cylinder hydraulic pre-punching and single-cylinder pre-cutting:

3 sets of punching dies

Single hole design with middle hole; 2.5mm, 3.5mm and 5mm master molds

Three sets, slot size: 14x25mm and round hole ø12, 14, 16, 18mm (ø12, 14, 16, 18 Of pins and dies. Offset and die: Cr12MoV (D2 steel);

Flat pump: hydraulic motor

Hydraulic motor power 22KW (China Mingda Shumo)

Solenoid valve brand: HUADE/YUKEN

3) Power transmission platform:

Length=12m, 1.5KW, handwheel positioning

4) Heavy-duty design, automatic variable diameter rolling mill

20-step to form, Through shaft type, linear guide; Shaft material: 40Cr steel, shaft diameter: ≥95mm

Main power: AC motor 30KW X2, variable diameter motor: 0.75KW * 2 + 2.2KW * 1

Roller material: Cr12 (D3 steel), precision machining, heat treatment.

5)Cooling system

6) Product Show

7) Decoiler

8 tons X650mm hydraulic decoiler (recycling type, with hydraulic towing pressure)

In the expand circle of the hydraulic system, the oil pump motor: 3KW (China)

8) PLC Control System

Brand: BMS Original: China

The whole line adopts PLC control system, touch screen adverbial clause: interface man-machine operation implementer

Interaction with PLC. The monitoring of the production process will be realized through program design. Operating

Parameter adverbial clause: the point where the fault indicator will be monitored by the operator

You can choose manual mode/automatic mode. PLC: SIEMENS (German brand)

Inverter: DELTA (brand) HMI (touch Taiwanese screen): SIEMENS (German brand)

Encoder: OMRON (Japanese brand); Display display≤±2 mm; Control voltage 24V

After-Sale Service

1. Within the 24 months, we will courier the replacement parts to the client free of charge

2. We offer technical support for the entire life of our machines

3. We can send our technicians to install and train the workers in the clients' factories with

extra cost

Packing method

Main body of machine is naked and covered by plastic film(to protect of dust and corrosion),loaded into

1. The warranty is 24 months after the client receives the machine.

container and steadily fixed in container suitable by steel rope and lock, suitable for long-distance transportation.

Gold supplier

Gold supplier

Facebook

Facebook  Twitter

Twitter  Linkedin

Linkedin  YouTube

YouTube  Blogger

Blogger  Instagram

Instagram